In the world of premium watchmaking, the choice of materials is a crucial factor that can make or break the success of a timepiece. While various materials have been used throughout history, stainless steel has emerged as a prime choice for watch manufacturers, offering an unparalleled combination of durability, corrosion resistance, and aesthetic appeal.

As a leading OEM/ODM watch manufacturer specializing in stainless steel timepieces, we understand the intricacies of selecting the right material for each project. This decision goes beyond mere aesthetics; it’s a delicate balance of performance, longevity, and craftsmanship that ultimately determines the quality and reliability of the final product.

In this comprehensive guide, we delve into the fascinating world of stainless steel watch materials, exploring the different alloy types, their unique properties, and how to select the perfect material for your desired watch design and style. Whether you’re a well-established brand seeking to launch a new collection or an entrepreneur embarking on a novel venture, this resource will equip you with invaluable insights to elevate your OEM/ODM watch manufacturing projects.

By understanding the nuances of stainless steel materials, you’ll gain a deeper appreciation for the factors that contribute to a timepiece’s durability, corrosion resistance, and overall aesthetic appeal. With this knowledge, you can make informed decisions that not only meet but exceed the expectations of your discerning customers.

So, let’s embark on this journey together, unveiling the secrets of stainless steel watch materials and unlocking the potential to create timepieces that truly stand the test of time.

An Introduction to Stainless Steel Watch Materials

Stainless steel is an alloy that has revolutionized the watch industry with its exceptional properties and versatility. Unlike traditional metals, stainless steel offers a unique combination of strength, corrosion resistance, and aesthetic appeal, making it an ideal material for timepiece construction.

At its core, stainless steel is an alloy composed primarily of iron and chromium, with the addition of other elements such as nickel, molybdenum, and manganese. The chromium content, typically ranging from 10% to 20%, is the key component that gives stainless steel its remarkable corrosion resistance. When exposed to oxygen, chromium forms an invisible passive layer on the surface, acting as a barrier against rust, tarnishing, and other forms of oxidation.

Beyond its resistance to corrosion, stainless steel boasts impressive durability and hardness, thanks to its unique metallurgical properties. This strength ensures that watch cases and bracelets can withstand the rigors of daily wear and tear, while maintaining their structural integrity and aesthetic appeal for years to come.

The versatility of stainless steel lies in its ability to be crafted into a wide range of designs, from sleek and minimalist styles to intricate and ornate patterns. Its lustrous surface can be polished to a mirror-like finish or given a brushed or satin treatment, catering to diverse aesthetic preferences.

In the world of watchmaking, stainless steel has become an industry staple, with numerous renowned brands and OEM/ODM manufacturers embracing its exceptional qualities. From luxury dress watches to rugged sports timepieces, this remarkable material has proven its worth time and again, making it a favorite among watch enthusiasts and connoisseurs alike.

Common Stainless Steel Alloy Types for Watches

While stainless steel is a broad term, it encompasses a range of specific alloy compositions, each with its unique properties and characteristics. In the world of watchmaking, certain alloy types have emerged as industry favorites, renowned for their exceptional performance and suitability for different watch styles and applications.

316L Stainless Steel:

One of the most commonly used alloys in watch manufacturing is 316L stainless steel. This austenitic grade steel contains chromium, nickel, and molybdenum, which impart superior corrosion resistance and durability. 316L is particularly resistant to pitting and crevice corrosion, making it an excellent choice for watches that may be exposed to harsh environments or saltwater. Its well-rounded properties and affordability make it a popular option for various watch styles, from casual to formal.

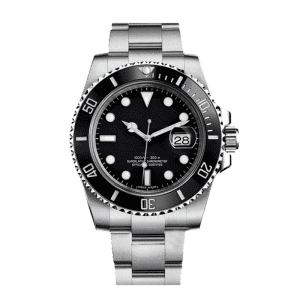

316L Stainless Steel Watch

904L Stainless Steel:

For those seeking the ultimate in corrosion resistance and durability, 904L stainless steel is a premium choice. This high-grade alloy contains higher levels of chromium, nickel, and molybdenum compared to 316L, resulting in exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking. 904L is often favored for high-end dive watches and professional timepieces subjected to extreme conditions. Its superior hardness also contributes to improved scratch resistance, ensuring your watches maintain their pristine appearance for years to come.

Rolex Submariner Steel 904L Stainless Steel Watch

SINN – German Submarine Steel:

This steel alloy places special emphasis on corrosion resistance, measured by its Pitting Resistance Equivalent (PRE) value. While regular 316L stainless steel has a PRE value of around 26, submarine steel, which must effectively combat seawater corrosion, typically has a PRE value above 32. The submarine steel used by SINN boasts an impressive PRE value of 38. Additionally, hardness is a standout feature of this alloy, with a Vickers hardness of 1500, significantly higher than the typical 220 Vickers hardness of regular stainless steel. Consequently, SINN’s German submarine steel watches offer superior protective properties.

German Submarine Steel Watch

Chopard – Lucent Steel A223

In 2019, when Chopard introduced the Alpine Eagle collection, they also developed the Lucent Steel A223, a proprietary stainless steel alloy. According to the brand, this steel’s wear resistance is 1.5 times higher than that of regular stainless steel, and it exhibits lower susceptibility to sensitization, boasting properties comparable to surgical steel. Its hypoallergenic nature ensures a comfortable wearing experience without the risk of allergic reactions. Moreover, the crystal structure of Lucent Steel A223 is relatively uniform, allowing for a highly polished, mirror-like finish that reflects light in a captivating manner.

Chopard – Lucent Steel A223 Watch

SEIKO – Ever-Brilliant Steel

As the name suggests, Ever-Brilliant Steel boasts a brighter, more lustrous surface compared to regular stainless steel. Conceptually similar to German submarine steel, this alloy prioritizes enhanced corrosion resistance. SEIKO’s 2020 releases, such as the 1965 Diver’s reissue and the 1968 Professional Diver’s 300m reissue, feature this material, which has a PRE value 1.7 times higher than regular stainless steel, making it an excellent choice for dive watches that must withstand prolonged exposure to saltwater environments.

SEIKO – Ever-Brilliant Steel Watch

Other Stainless Steel Alloys:

While 316L and 904L are among the most popular choices, the world of stainless steel alloys is vast and diverse. Alloys like 317L, known for its resistance to chloride-induced corrosion, or 420, a martensitic grade with high hardness and strength, may be preferred for specific applications or watch designs.

Each alloy type offers its unique strengths and characteristics, tailored to meet the demands of different watch styles, environments, and performance requirements. Understanding these nuances is crucial in selecting the most suitable material for your OEM/ODM watch manufacturing projects, ensuring your timepieces not only look stunning but also withstand the test of time.

Unique Properties of Stainless Steel Alloys

While all stainless steel alloys share common traits like corrosion resistance and durability, each specific grade exhibits unique characteristics that set it apart. Understanding these distinct properties is crucial when selecting the ideal material for your watch design and intended use.

Corrosion Resistance and Oxidation Resistance:

One of the primary reasons for choosing stainless steel in watchmaking is its exceptional resistance to corrosion and oxidation. Alloys like 316L and 904L boast superior corrosion resistance due to their higher chromium and molybdenum content, which helps form a robust passive layer on the surface. This passive layer acts as a barrier against rust, pitting, and other forms of corrosion, ensuring your watches maintain their pristine appearance even in harsh environments.

Hardness and Wear Resistance:

The hardness of a stainless steel alloy is a critical factor in determining its ability to withstand scratches, dents, and other forms of surface damage. Alloys like 904L and certain martensitic grades like 420 offer exceptional hardness and wear resistance, making them ideal for watches subject to heavy use or exposed to abrasive conditions. This added durability ensures your timepieces retain their aesthetic appeal for years to come.

Aesthetic Qualities:

While functionality is paramount, the aesthetic appeal of a watch cannot be overlooked. Stainless steel alloys offer a range of visual qualities, from the lustrous sheen of austenitic grades like 316L to the more muted satin finishes of martensitic alloys. This versatility allows watchmakers to create timepieces that not only perform exceptionally but also align with various design aesthetics, catering to diverse consumer preferences.

By understanding the unique properties of each stainless steel alloy, you can make informed decisions that balance performance, durability, and aesthetics, ensuring your OEM/ODM watch manufacturing projects deliver products that exceed expectations.

Selecting the Right Stainless Steel for Your Watch Style

With a diverse array of stainless steel alloys at your disposal, choosing the most suitable material for your watch design and style becomes paramount. Each watch category presents unique challenges and requirements, demanding specific material properties to ensure optimal performance and aesthetic appeal.

Dress Watches:

Elegance and Sophistication For dress watches, where elegance and sophistication are key, alloys like 316L stainless steel strike the perfect balance. Its corrosion resistance and durability ensure your timepieces maintain their pristine appearance, while the alloy’s lustrous finish and polished surfaces complement the refined aesthetics of formal attire. The versatility of 316L also allows for intricate case designs and bracelet patterns, enabling you to create truly distinctive dress watches.

Sports Watches:

Durability and Ruggedness When it comes to sports watches, durability and ruggedness are paramount. Alloys like 904L stainless steel excel in this domain, offering exceptional hardness and wear resistance to withstand the rigors of an active lifestyle. Whether your OEM/ODM sports watch is designed for hiking, cycling, or extreme adventures, the superior corrosion resistance of 904L ensures it can endure exposure to harsh environments without compromising its performance or appearance.

Dive Watches:

Uncompromising Corrosion Resistance For dive watches, corrosion resistance is the most critical factor, as they must endure constant exposure to saltwater and high-pressure environments. Alloys like 904L and 317L, with their outstanding resistance to pitting and crevice corrosion, are ideal choices for professional-grade dive watches. These alloys ensure your timepieces can withstand the rigors of underwater exploration while maintaining their structural integrity and aesthetic appeal, even after prolonged immersion.

By carefully considering the unique requirements of your watch style, you can select the stainless steel alloy that optimizes performance, durability, and aesthetic appeal, delivering products that resonate with your target audience and solidify your brand’s reputation for quality and craftsmanship.

Material Selection Strategies for OEM/ODM Watch Manufacturing

In the world of OEM and ODM watch manufacturing, selecting the right stainless steel material is a critical decision that can significantly impact the success of your projects. As a trusted partner in this industry, we understand the importance of balancing various factors to ensure our clients receive products that meet their exact specifications and exceed customer expectations.

Balancing Cost, Performance, and Aesthetic Demands

One of the key challenges in material selection is striking the right balance between cost, performance, and aesthetic requirements. While premium alloys like 904L offer unparalleled durability and corrosion resistance, they may not always be the most cost-effective choice for every project. Our expertise lies in analyzing your specific needs and recommending the most suitable material that delivers the desired performance and aesthetic appeal while aligning with your budgetary constraints.

Ensuring Consistency and Traceability

In the realm of OEM/ODM manufacturing, consistency and traceability are paramount. We implement stringent quality control measures to ensure that every batch of stainless steel material meets the highest standards and specifications. Our robust supply chain and material tracking systems enable us to guarantee the authenticity and quality of the alloys used in your watch production, providing you with complete peace of mind.

Collaborative Partnerships with Trusted Suppliers

Our success in material selection is further bolstered by our long-standing partnerships with trusted suppliers of premium stainless steel alloys. These collaborations allow us to stay ahead of the curve, gaining early access to the latest material innovations and developments. By working closely with industry leaders, we can offer our clients cutting-edge solutions tailored to their unique requirements, solidifying our position as a forward-thinking OEM/ODM watch manufacturer.

With our extensive expertise, state-of-the-art facilities, and commitment to excellence, we are well-equipped to guide you through the intricate process of material selection, ensuring your OEM/ODM watch manufacturing projects are executed with precision, quality, and efficiency.

In Conclusion: Mastering the Art of Stainless Steel

Throughout this comprehensive guide, we have explored the fascinating world of stainless steel watch materials, unveiling the unique properties, strengths, and versatility of various alloy types. From the workhorse 316L to the premium 904L, each alloy offers distinct advantages that cater to different watch styles, performance requirements, and aesthetic preferences.

By understanding the nuances of corrosion resistance, hardness, wear resistance, and aesthetic qualities, you can make informed decisions that elevate the quality and durability of your OEM/ODM watch manufacturing projects. Whether you’re creating elegant dress watches, rugged sports timepieces, or professional-grade dive watches, selecting the right stainless steel alloy is crucial in ensuring your products not only meet but exceed customer expectations.

As a leading OEM/ODM watch manufacturer, we take pride in our expertise and commitment to delivering excellence at every stage of the production process. Our material selection strategies, rooted in balancing cost, performance, and aesthetic demands, combined with our stringent quality control measures and collaborative partnerships with trusted suppliers, make us the ideal partner for your watch manufacturing needs.

Embrace the enduring allure of stainless steel, and let us guide you in mastering the art of material selection. Together, we can create timepieces that not only captivate audiences with their beauty but also withstand the test of time, solidifying your brand’s reputation for quality, craftsmanship, and innovation.

Related Posts

- Advantages Of Stainless Steel For OEM/ODM Watch Manufacturing

- The Difference Between Automatic And Hand-Wound Movements

- China Watch Factory – Custom Watch Manufacturing Services

- The Anatomy Of A Watch – Understanding The Different Parts

- ODM Vs OEM Watch: Understanding The Difference In Watch Manufacturing Services

- How To Find The Best Watch Manufacturing Company For Your Needs

- How Much Does It Really Cost To Manufacture Your Own Watch?

- Boosting Brand Awareness Through Custom Logo Watches

- The Ultimate Guide To Watch Movements: Types, Mechanisms, And Brands